From Formulation to Distribution: SAP B1 for Pharma Excellence by Qnomix

I. From Raw Materials to Finished Products: Complete Pharma Traceability with SAP B1

Our SAP B1 for Pharma helps pharmaceutical companies to effectively control intricate formulations, batch production, and serialization. With the SAP B1 production module and custom addons, companies are able to monitor each batch of raw materials to finished products. It also provides complete traceability, which makes GMP compliance easy, enhances auditing, allows quick recall management, which minimizes errors and protects product integrity, and streamlines production processes.

II. Automated QA and Compliance – Meeting FDA, WHO, and ISO Standards

Production of Pharma requires strict compliance with the FDA, WHO, and ISO standards.SAP Business One for pharma also incorporates the SAP B1 QC addon, CAPA tracking, batch-level inspection, and automated regulatory reporting. Qnomix Technologies helps pharmaceutical plants to achieve a high level of consistency, minimize the chance of non-compliance, and make sure that each lot is produced to international safety and regulatory standards without slackening production.

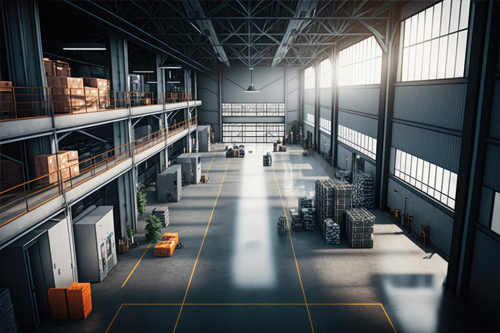

III. End-to-End Inventory and Supply Chain Optimization for Pharma Manufacturing

ERP for pharma provides complete visibility of raw materials, work in progress, and completed medicines. Through SAP B1 inventory management, pharmaceutical manufacturers are able to control cold chain compliance, streamline warehouse operations, and cut down wastage. Combined financial modules offer actionable feedback to cost management, allowing firms to optimize efficiency, ensure regulatory compliance, and maximize profitability, as well as support scaling-up operations fast.

7 Pharmaceutical Manufacturing Challenges Solved by SAP Business One – Qnomix Technologies

1. Complex Formulations and Batch Variability

Multi-ingredient formulations used in pharmaceutical processes should be uniform between batches.

I. Solution: In pharma, SAP B1 handles batch production, multi-level BOM, as well as serialization that will provide accurate allocation of raw materials and consistency in yield.

II. Impact: Manufacturers are able to maintain consistent product quality, minimizing waste, and batches are simplified so that they can be audited by the regulator.

2. Regulatory Compliance Pressure (FDA, WHO, ISO, GMP)

Adopting international standards is not simple and is time-consuming.

I. Solution: SAP Pharma Business One combines SAP B1 QC addon, CAPA tracking, and automatic compliance reporting.

II. Impact: Firms’ effectiveness in complying with regulations, minimizing the risks of inspections, and easing tasks with regard to audit procedures is realized.

3. Risky Handling of Hazardous Materials

Active pharmaceutical ingredients (APIs) and hazardous compounds are involved in the production of pharmaceuticals.

I. Solution: SAP B1 storage control addon and customer-built safety process in use to view the storage conditions, shelf-life, and handling of goods.

II. Impact: There were fewer accidents, safer operations, and better protection of the staff.

4. Procurement Delays and Stock Shortages

Production schedules are interrupted by the late delivery of materials.

I. Solution: The pharma ERP automates the purchase orders, vendors, and monitors the lead time.

II. Impact: Availability of raw materials on a just-in-time basis, improved downtime, and an efficient supply chain.

5. Inconsistent Product Quality and Rework

Defective batches result in recalls and revenue loss.

I. Solution: THE SAP B1 production module contains (batch-level) QA inspections that promote early identification of deviation.

II. Impact: Reduced rework, scrap, and high-quality standards in all batches.

6. Production Bottlenecks and Equipment Downtime

The inefficient scheduling and machine failures hamper the output.

I. Solution: SAP B1 plant maintenance addition, and a real-time monitoring dashboard monitors OEE and preventive maintenance schedules.

II. Impact: Increased equipment uptime, enhanced production processes, and streamlined throughput.

7. Difficulty Scaling Multi-Site Operations

As the operations are expanded, this usually leads to inconsistencies.

I. Solution: Integrating SAP Business One and pharmaceutical manufacturers has a chance to streamline their processes in different locations and obtain serialization, QA, and inventory control at the heart of operations.

II. Impact: Quality product consistency, simplified compliance, and easy scaling to global growth.

Transform Complexity into Control in Pharmaceutical Manufacturing