Optimizing Rolling, Casting, and Finishing – SAP B1 for Steel Industry Leaders

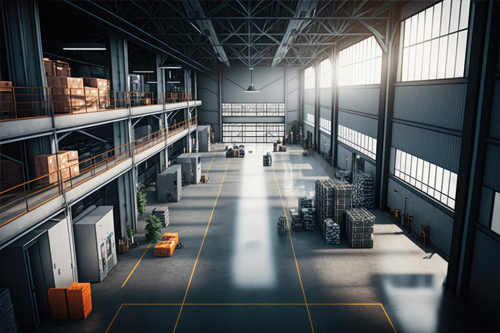

I. Optimizing Steel Production Processes with SAP B1

The process of steel manufacturing includes casting, rolling, and finishing processes that require accuracy and effectiveness. Using SAP B1 production module and inventory management, Qnomix technologies allow real-time monitoring of raw iron, billets, slabs, and finished steel, wastage is minimized, and bottleneck in production is minimized, and consistency is maintained during production in multiple plants.

II. Quality Assurance and Compliance in Steel Manufacturing

It is important to keep tensile strength, chemical composition, and surface finish during steel production. SAP B1, featuring QC addon and custom addons, offers inline quality checks, defect reporting, and compliance reporting to assist manufacturers in complying with ISO and ASTM, as well as industry-specific standards.

III. Supply Chain and Vendor Collaboration Optimization

IV. Forging Flexibility – Scalable Operations for Modern Steel Manufacturing

SAP B1 can manage workflow, projects, and offer production analytics in multi-site operations. It offers flexibility, cost management, and scalability to manufacturers to roll mills, forging, and finishing lines in a manner that is responsive to changes in demand and market expansions.

A Day Inside a Steel Plant: How SAP B1 Drives Precision and Performance

1. Morning Stock Management – Real-Time Inventory Control for Raw Materials

2. Furnace Operations – Automated Production Planning and Energy Optimization

3. Casting and Rolling – Workflow Automation for Precision Manufacturing

Manufacturing of office and commercial furniture is characterized by a large volume and multiple products. SAP B1 can facilitate batch tracking, coordination of the procurement process, and control over quality so that businesses can meet strict deadlines and deliver uniformity between a variety of lines.

4. Quality Checks – Inline Inspection and Compliance with Global Standards

After slabs or coils are made, the QC addon combines non-destructive testing (NDT), surface finishing tests, and tensile strength tests. Non-conformance reports (NCRs), corrective and preventive actions (CAPA) alerts guarantee that each of the batches fulfills the standards of ISO and ASTM, among other regulations, to minimize waste and improve brand perception.

5. Maintenance and Safety – Ensuring Equipment Health and Worker Safety

6. Procurement Intelligence – Smarter Supplier Collaboration and Lead-Time Tracking

Tailor-made extensions and vendor connectivity programs fully automate purchase orders, vendor evaluations, and lead-time management. An almost perfect coordination with the suppliers implies that the essential raw materials are provided on time, which results in continuous operations even in the event of a disruption in the supply chain.

7. Energy Management – Reducing Operational Costs with Analytics

Furniture that comes with either IoT or ergonomic design will need complicated component tracking and assembly monitoring. The integration modules and production analytics of SAP B1 allow manufacturers to effectively integrate technologies and keep the quality of the product high.

8. Regulatory Compliance – Documentation and Reporting Made Seamless

ISO, ASTM, and environmental board compliance requirements were automated. Emission tracking, waste management modules, and batch-level reporting ensure compliance with regulations and avoid administrative overheads to allow manufacturers to concentrate on production excellence.

9. End-of-Day Insights – Integrated Reporting and Decision Support

The managers have real-time KPI boards that assist them in assessing the efficiency of the production, energy consumption, and inventory utilization. Together with the production data, the financial reports enable tracing costs, analyzing variance, and plan future orders, and this is important in making long-term strategic decisions that are most likely to be executed.

10. Continuous Improvement – Data-Driven Innovation and Lean Manufacturing

The manufacturers can use Six Sigma, lean manufacturing, and Total Quality Management (TQM) programs with historical data, predictive analytics, and performance reporting. SAP B1 enables the team to locate the areas of inefficiency, streamline the workflow, and develop new-generation steel products.

Empowering Steel Manufacturers with SAP B1 – A New Era of Precision and Growth

In the current steel industry, where there is high competition, agility in supply chains, product quality, and operational efficiency are not negotiable. SAP B1 for steel industry gives manufacturers a chance to manage the inventory, production module, QC addon, and plant maintenance addon to streamline resources, decrease downtime, and adhere to strict ISO and ASTM compliance standards. SAP B1, with real-time analytics, energy optimization, and scalability of multiple sites, makes the steel production smarter, safer, and more profitable. ERP for steel industry is the key to sustainable growth and leading the industry.